Contract Manufacturing of Components and Hardware

Contract Manufacturers or component parts are have some unique needs that are very different form typical distributors which software is modeled after.

Hardware – sourcing of product

The sourcing of product can be managed and simplified by utilizing tools to take customer requests and turn them into RFQ’s which get sent out to multiple factories. When price quotes are received back in from suppliers they can be analyzed and compared, and by using the price estimator tool users can estimate what the additional costs will be (Ocean Freight, Trucking, Duty, Customs Fee’s, etc.) and factor in a mark up to come up with a price we should be quoting the customer.

Hardware – Order Processing

For these businesses all component items are custom designed for the customer and pre-sold prior to placing an order with the factory so the order processing can be streamlined by managing the Purchase Order (order to factory), and Sales Order (Customer Order) all from the same screen (see below).

Hardware – Tracking Shipments

To be able to service customers appropriately, contract manufacturers need to be able to quickly and easily tell customers the status of open orders and when they can expect delivery. In addition, the companies need to stay on top of the factories to be sure that product and shipping stays on schedule. VISCO offers several tools and reports to help in this process.

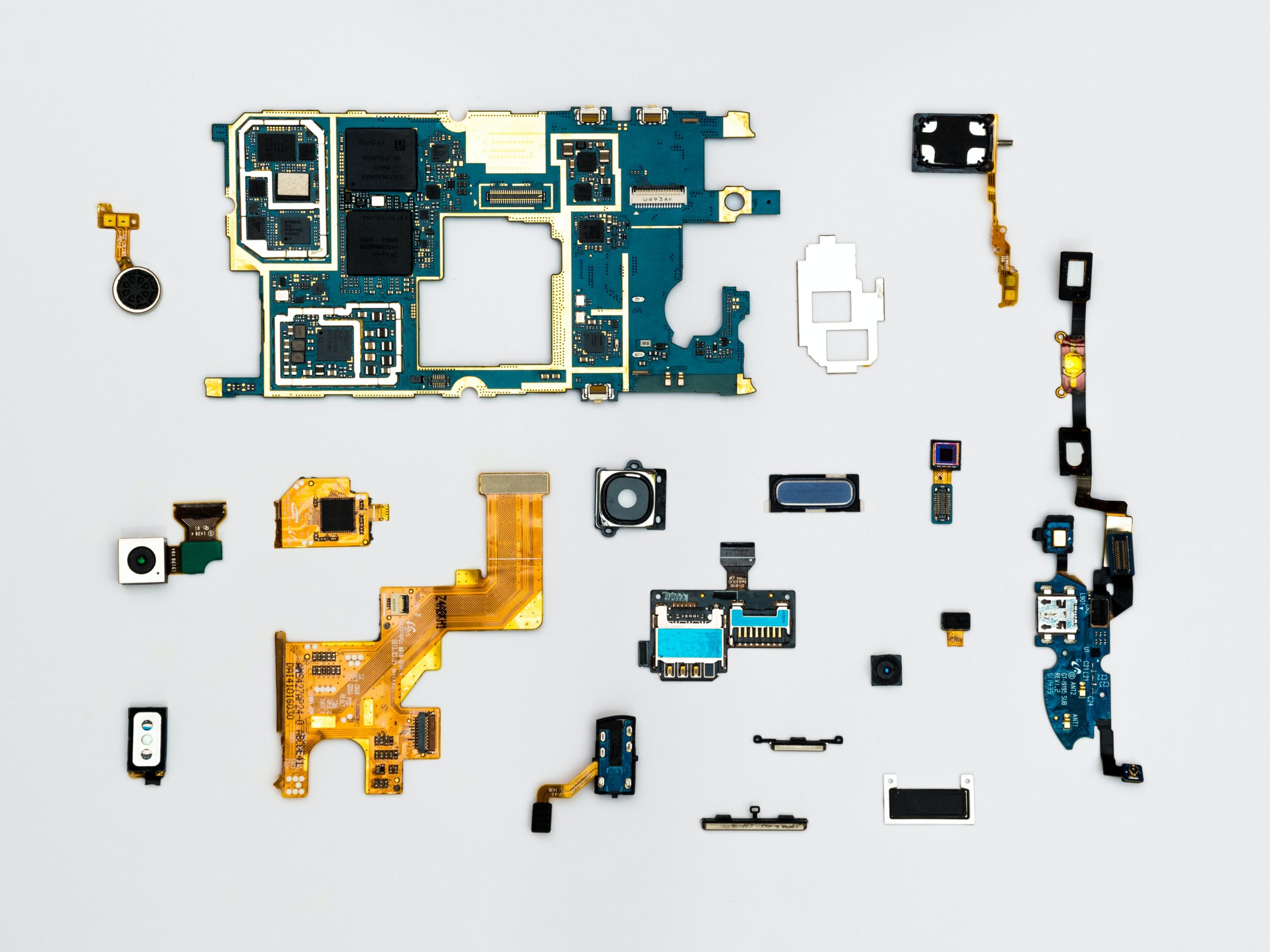

Hardware – Industrial Parts

Importers of Industrial Parts may have products ranging from the smallest nut or bolt to a large piece of machinery. VISCO can track these parts from the smallest to the largest and determine their costs. Inventory can be tracked while it is being transported as well as from warehouse to warehouse.

VISCO was designed to meet the specific needs of the industrial parts and hardware industry by including features such as:

- Grouping merchandise by size and functionality.

- Remote Access for manufacturing facility over seas

- Allocation system to “ear mark” inventory that is either “in transit” or still at manufacturers facility

- USTA #

- Vendor Evaluation to track “lateness” by vendor