Some of our customers manage inventory at several different warehouse locations. We often hear concerns about under or over buying goods, losing track of product, and communication to and from warehouse staff. With VISCO’s customizable inventory management tool, you too can get a handle on inventory in one or many warehouses.

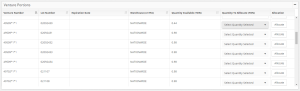

Inventory is tracked based on inbound shipments from vendors, every shipment of goods being brought into the warehouse will be affiliated with the container or Bill of Lading that the goods came in on. Each shipment on a container is a shipment from a purchase order. When receiving goods in VISCO, the user will choose the warehouse those goods will be staying at. If your company uses lots to keep track of product, the lots can be assigned to specific product. This makes searching for or allocating to specific lots especially easy.

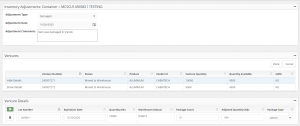

Users can change or edit quantity, packaging and package types of items coming in. Lets say you buy in Metric Tons, but you package as sacks and sell by the pound, a user can distinguish how many packages are in a shipment and what they contain.

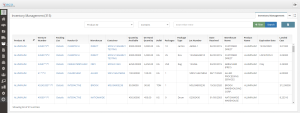

Inventory management shows you what quantity is available and what is on hand. Meaning it will show you what is physically sitting at a warehouse and what of those items are already saved for a specific customer. That way you see a real depiction of quantity in warehouse so you can more accurately buy product when needed.

VISCO allows you to keep track of expiration dates on product and get notifications when they are approaching. Set reorder points for specific products. alerts to notify when items are getting low. In the past we have customized reorder points for product in each warehouse being used and set up email

By Clicking into the “Analysis” link on a specific lot you can see a breakdown of how the landed cost for that lot is calculated. By clicking into the “Packing List” for that lot you can drill down into the lot history for that lot.

The system also offers a forecast report that allows the user to see exactly what is coming in based on the vendor’s production schedule and depending on ETAs, what will be available throughout the month, year and beyond. Watch our video on the Forecast Report to learn more.