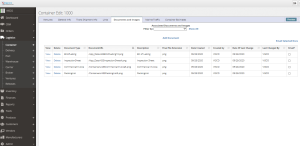

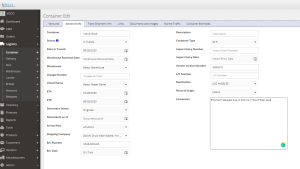

Users can build containers by selecting Purchase Order(s) or portions of a PO and adding them to the container. The system can present a warning message to the user if the container is going to be over weight or over filled by volume by comparing the weight and/or CBM per carton to the container capacity. This process can be done during a staging process so they are letting the suppliers know what to ship or once they receive the shipping documents from the vendor letting them know what is shipping.

Logistics:

Once the container is built, users can track logistics details including all of the shipping information about the container:

- Port of Origin

- Port of Arrival

- ETD

- ETA

- Shipping Company

- Invoice Number

- B/L number

- B/L Date

This data can be entered manually by users or can be updated automatically using the Vizion Container Tracking Service

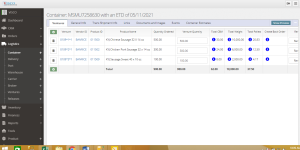

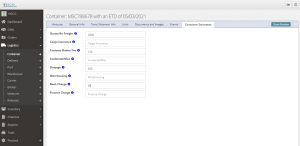

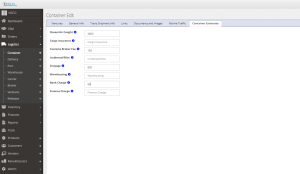

Costing

The system will help to calculate landed costs on each item shipping by allowing the user to enter costs (actual or estimated) against a particular shipment which will then be distributed against all items in that container. Note that estimated costs can be calculated by the system or entered manually by the user and when costs are distributed across the items in the container this can be done by weight, volume, value, or other custom distribution methods. Typical Costs include:

- Ocean Freight

- Drayage

- Duty

- Cargo Insurance

- Warehousing

- Finance Charges

- Bank Fees

- Customs Broker Fees

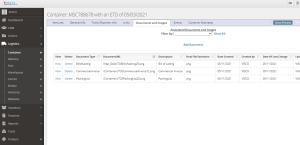

Documents

Each shipment will have its own unique document library which can be uploaded if they are coming from outside sources (Packing List, Commercial Invoice, Bill of Lading, Certificate of Origin, etc) or system generated (Container Instructions, ISF, Warehouse Arrival, Delivery Order).

Document Alerts and Checklists

Using a built in alert system, the system is designed to alert users before potential shipping document issues occur. For example, if products are FDA regulated then the system will alert the user if FDA required documents have not been filed. In addition, users can keep a checklist of all shipping document tasks and there are built in tools assisting in the shipping workflow.

- Copy B/L and Invoice received

- Copy B/L and Invoice sent

- ISF Submitted

- Certificate of Origin Received

- Certificate of Analysis Received

- Inspection Certificate Received

- Warehouse Notified

- Last Free Day

- Customs Inspection Hold

- FDA Hold

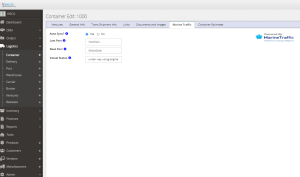

Manage Container Logistics

Automatic Shipment Updates Provided by Marine Traffic

Automatic Shipment Updates Provided by Marine Traffic Upload Shipping Document

Upload Shipping Document